Medical devices, and especially implants, require an outstanding quality which can only be achieved by controlled processes and continuous inspections and measurements.

MeKo performes a 100 % final visual inspection of all components for implants (stents, heart valves, clips, …) in order to ensure highest quality.

Special trained inspectors operate the instruments. MeKo provides ergonomic work places to improve inspectors’ concentration.

Through the use of automatic microscopes hundreds of measurements can be taken on a single work piece.

The results of these measurements ensure our customers the highest level of measurement confidence possible.

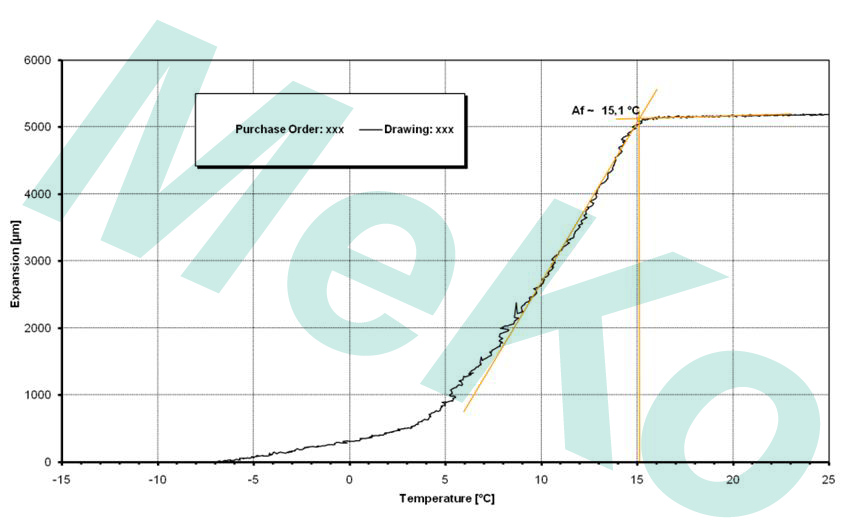

The Bend and Free Recovery (BFR) method is applied for measuring the active Af temperature of NiTi devices.

Please see also DSC below

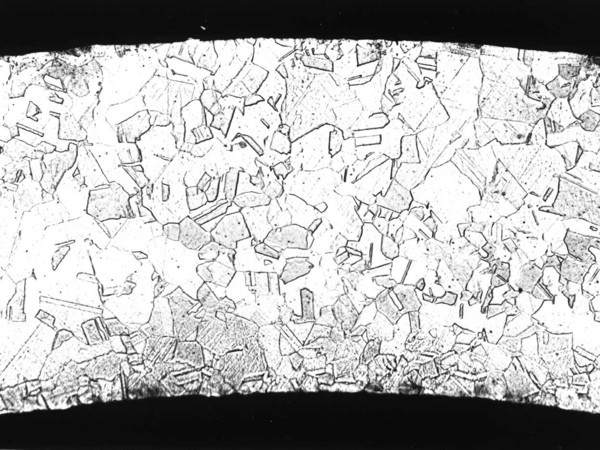

We take cross sections of devices to analyze grain structures, heat affected zones of laser welds, ...

MeKo performs in-vitro degradation tests for magnesium scaffolds:

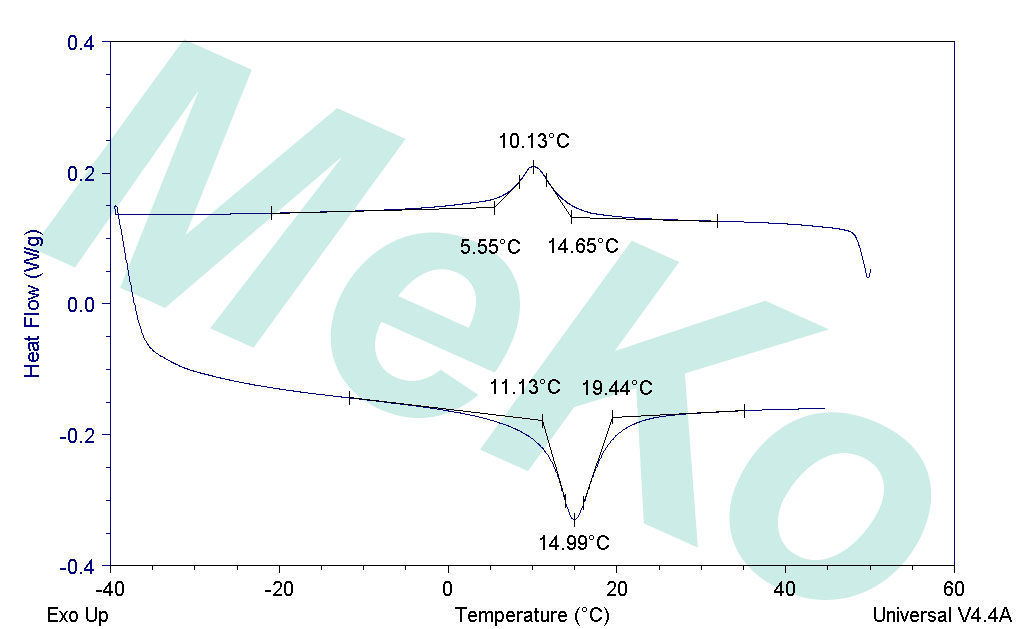

Utilizing DSC, MeKo determines the transformation temperatures (Af temperatures) of shape memory alloys like NiTi (Nitinol).

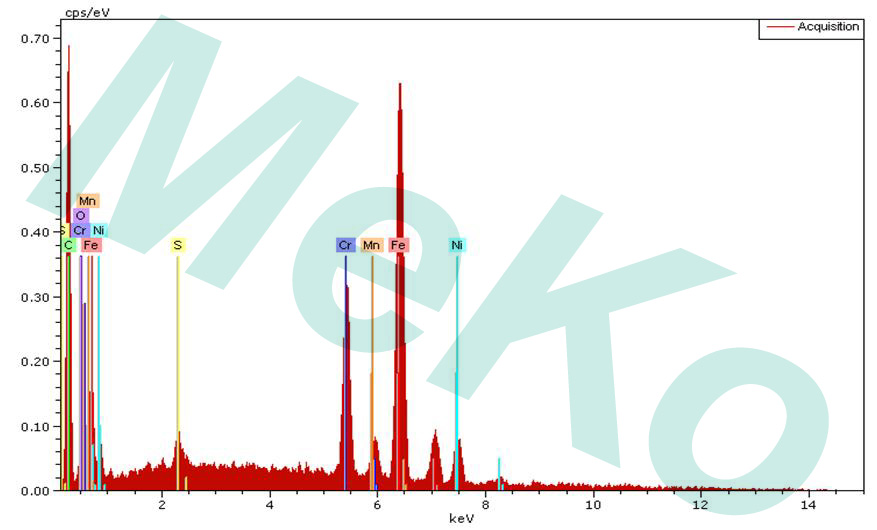

With our EDS system, material compositions and surface contaminations are analyzed.

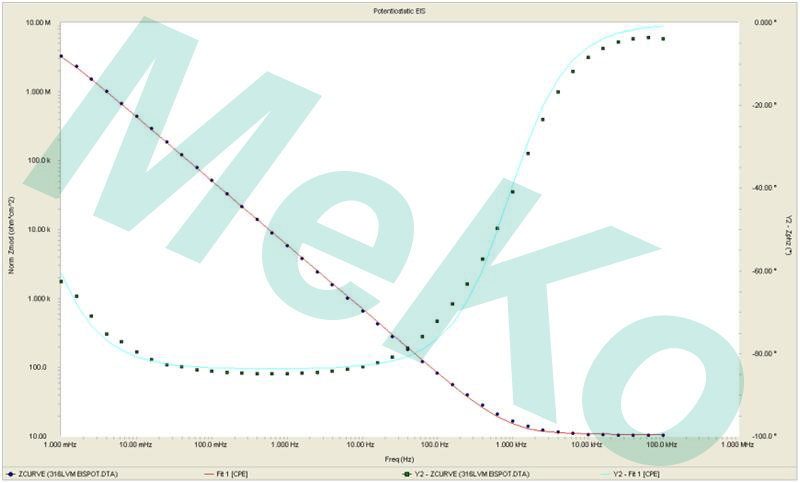

The EIS is typically applied to measure the AC-current and AC potential.

In corrosion testing, EIS is standard practice for measuring the polarization resistance (Rp) of corroding systems.

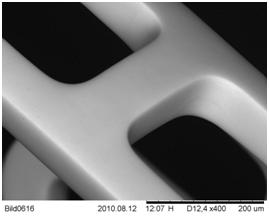

Using Scanning Electron Microscopes (SEM), MeKo investigates devices with high resolution and a magnification up to 30,000x.

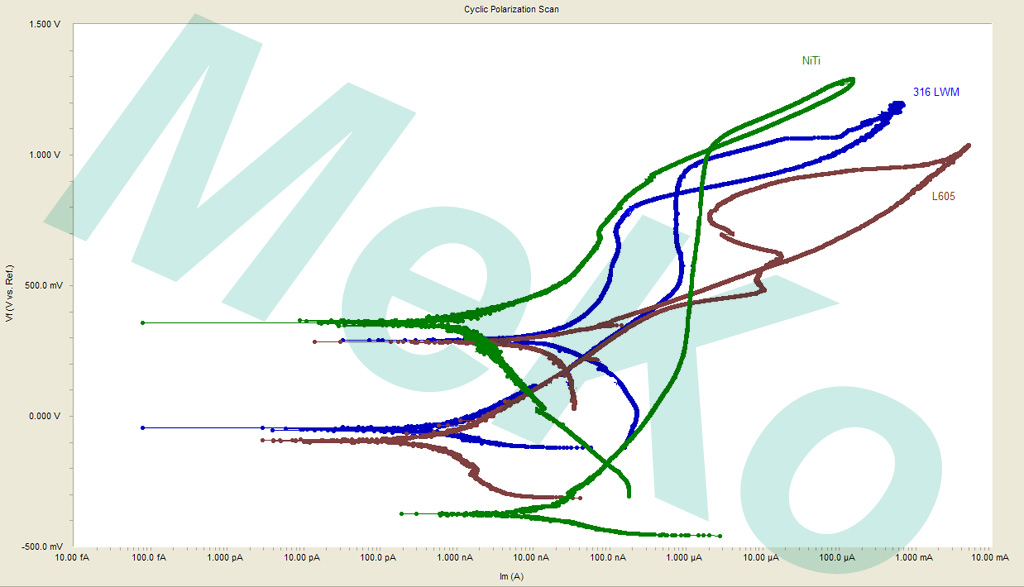

With potentiodynamic measurements the passivation and corrosion resistance of products are analysed in accordance with ASTM F2129.

We analyze surface roughness using a variety of testing methods, including contact stylus profilometry and confocal laser scanning microscopy.

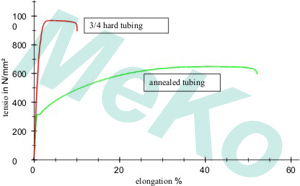

At MeKo, we know how to change the mechanical properties of implant materials by means of heat treatment.

To document the results, MeKo does not only check the time-temperature-curves of each heat treatment but also verifies the results by tensile tests.