Heat Treatment

- Extremely fine-grained structure

- LowElast process to reduce stent springback

Finest Grain Size for Excellent Durability

Heat treatment is an important, often underestimated technology used to adjust the mechanical properties of medical components and ensure reliable results. Thanks to our many years of experience at MeKo, we are experts in the heat treatment of 316LVM, L605, Phynox, MP35N, Nitinol, and many more.

- Large selection of different furnaces: chamber furnaces, salt bath furnaces, vacuum furnaces, fluidized bathes

- For 316L (316LVM), L605, Phynox, MP35N: annealing processes, grain refinement, and adjustment of material properties

- Special LowElast heat treatment technology

- Quality control

- Tensile tests

- Metallographic analysis of cross-sections

Our vacuum furnaces guarantee the finest grain size for annealed stainless steel implants with excellent elongation and lifespan. For cobalt-chrome alloys, the in-house process Low-Elast reduces the springback effect of crimped and the recoil behavior of expanded implants such as stents.

LowElast – The Heat Treatment for L605 Stents

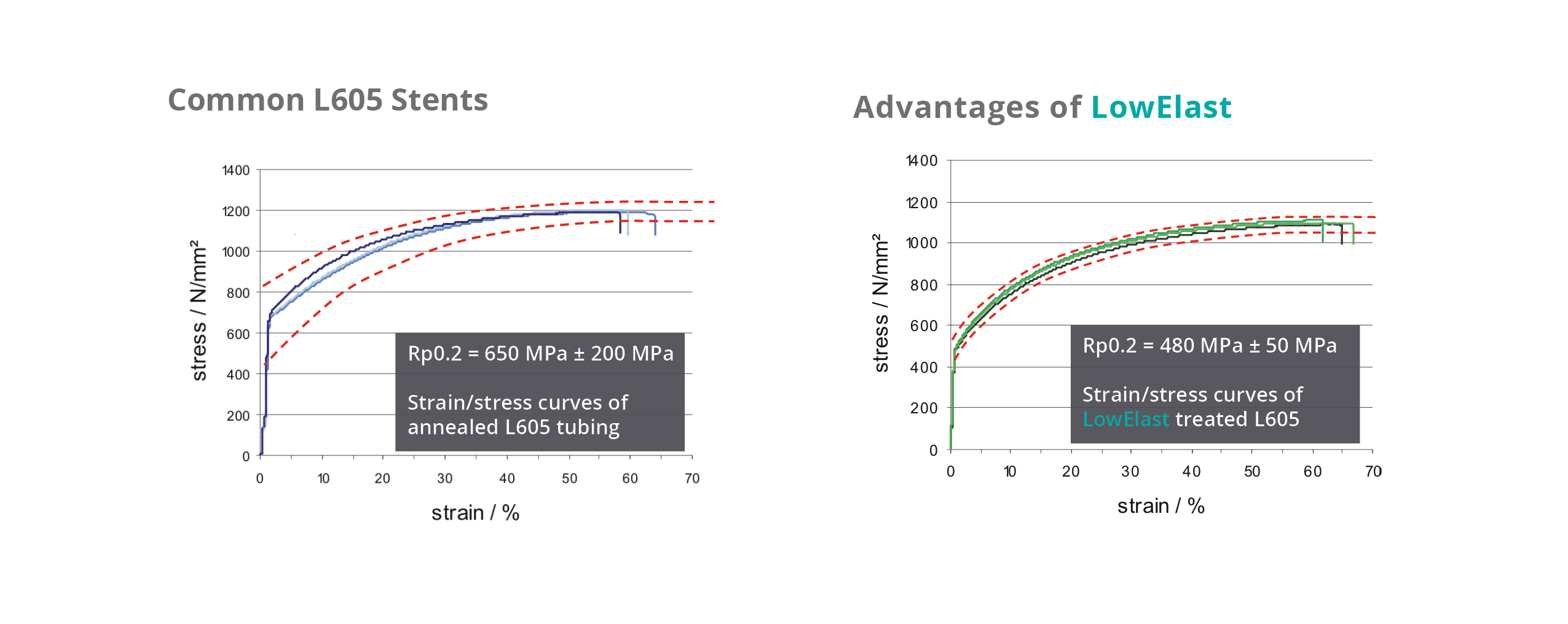

Balloon-expandable stents must adhere firmly to the balloon catheter to ensure safe delivery and precise placement. However, L605 stents are difficult to crimp due to their elastic strain. This results in a spring-back effect: after crimping, the stent tends to reopen slightly, reducing retention force and increasing the risk of balloon slippage or damage.

LowElast is MeKo’s specialized heat treatment engineered to solve these challenges. By lowering the yield strength of L605 while maintaining ultimate strength, LowElast reduces the spring-back effect and minimizes stent recoil after expansion. This results in significantly improved crimping behavior and higher retention forces compared to conventionally L605.

Why LowElast?

-

Reduced Spring-Back Effect

Lower yield strength minimizes elastic recovery, ensuring the stent remains tightly crimped. -

High Retention Forces

Secure adhesion of the stent on the catheter balloon for safe and reliable implantation. -

Stable, Adjustable Mechanical Properties

Mechanical values can be fine-tuned and remain consistent across batches. -

Reduced Recoil

Stents show less tendency to shrink back after expansion, supporting optimal vessel scaffolding. -

Lower Crimping Forces

Eliminates the need for over-crimping, reducing the risk of balloon catheter damage.

Why Conventional Annealing Is Not Enough

Annealed L605 tubing requires straightening, which alters yield strength and leads to slightly inconsistent results. In addition, L605 is significantly more sensitive to variations in heat treatment than stainless steel (316LVM), and its mechanical properties vary more from tube to tube and lot to lot compared to stainless steel.

MeKo has developed custom-built furnaces and the proprietary LowElast process, designed specifically for L605. This ensures stable and reproducible mechanical properties — yield strength, UTS, and elongation — enabling predictable, high-quality stent production.

Key Benefits for Your Stent Systems

- Higher retention forces for balloon-expandable L605 stents

- Reduced recoil and spring-back

- Consistent crimping behavior and reproducible results

- Lower balloon stress, minimizing catheter damage risk

With LowElast, L605 stents achieve crimping performance comparable to 316LVM — without sacrificing the strength advantages of cobalt-chromium alloys.