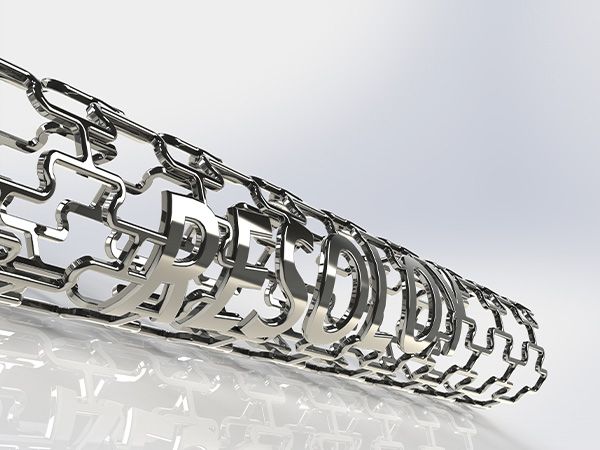

Resoloy®

The Future of Resorbable Implants

Resoloy® is MeKo’s proprietary magnesium-based alloy developed for next-generation bioresorbable implants. With its exceptional mechanical strength and carefully controlled degradation Resoloy® is ideally suited for temporary scaffolding during the healing process — particularly for cardiovascular applications.

Unlike traditional implants, Resoloy® is fully absorbed by the body after serving its purpose, reducing long-term complications such as chronic inflammation, implant fatigue, or the need for follow-up surgeries. The result? Better patient outcomes, faster recovery, and reduced overall healthcare costs.

Engineered for precision and safety, Resoloy® features an optimized corrosion profile, outstanding biocompatibility, and excellent radiopacity. Whether you need high-precision tubing or custom-fabricated components, MeKo delivers tailored solutions that integrate seamlessly with your medical device design.

Discover Resoloy® — where innovation meets healing and patient care.

Properties of Resoloy®

Compared to PLLA, Resoloy® offers about three times higher strength, thinner struts, higher radial force, and is suitable for direct stent placement via balloon catheter. Coatings can adjust the degradation time from a few months (pure Resoloy®) to the desired lifespan. In addition to proven biocompatibility, Resoloy® has no shelf life and no temperature issues.

Bioresorbable

Residual-Free Degradation - "leaves nothing behind"

Biocompatible

Adjustable degradation time and mechanical properties

MRI-compatible

Increased Radial Force

3 x higher than that of PLLA

Customizable Characteristics

The process supports highly customizable material characteristics, including break elongation of up to 40 % and tensile strengths reaching 300 MPa, made possible through alloy adjustments and specialized manufacturing techniques. This level of customization allows for unparalleled design flexibility, empowering our customers to create implants that truly meet the individual project requirements.

Improved Marker Material

Another highlight is our innovative marker material, designed to be highly visible under X-ray without causing galvanic corrosion, providing a reliable and safe solution for advanced implant designs. The marker is securely fixed using precise laser welding, ensuring a stable position and preventing it from dislodging.

Tubes in Stock

Ø 1,80 mm x 0,160 mm (Ø 0,071“ x 0,0063“)

Ø 2,20 mm x 0,160 mm (Ø 0,087“ x 0,0063“)

Ø 3,15 mm x 0,215 mm (Ø 0,124“ x 0,0085“)

Other tube dimensions available on request.

Functionality of Magnesium Alloy Resoloy®

Extensive in vitro and in vivo tests have been conducted for a scientific study on the degradation of vascular scaffolds (bioresorbable stents) made from the magnesium alloy Resoloy®. The results confirm that the degradation time of Resoloy® can be adjusted thanks to a double coating with fluoride and polymers. A significantly slower degradation is achieved in vitro compared to Magmaris®. Another advantage is that Resoloy® degrades without residues.

Animal experiments confirm the in-vitro results from the test laboratory and show that Resoloy® is highly biocompatible. The results of the published study demonstrate the high level of safety and efficacy of the alloy.

Research

In-vivo Studies

MeKo conducts in-vivo studies for animal experiments in renowned laboratories:

- Favorable in-vivo results for Resoloy® coronary scaffolds

- Ex-vivo degradation analysis using computed tomography and SEM/EDS

- OCT/QCA analysis

- Synchrotron examination

Degradation Testing Laboratories

MeKo conducts in-vitro degradation tests for Mg scaffolds:

- Simulated blood circulation

- Controlled flow rate, pressure, pulsation, and temperature of circulation

- Blood substitute solution for standardized tests: PBS, SBF, ...

- Fast and reproducible degradation evaluation

- Monitoring and visualization of the degradation process

- Prediction of in-vivo degradation behavior

MeKo Degradation Lab

MeKo Degradation Lab In-vivo Studies

In-vivo Studies Tube Stock

Tube Stock