New Laser Welding Sample

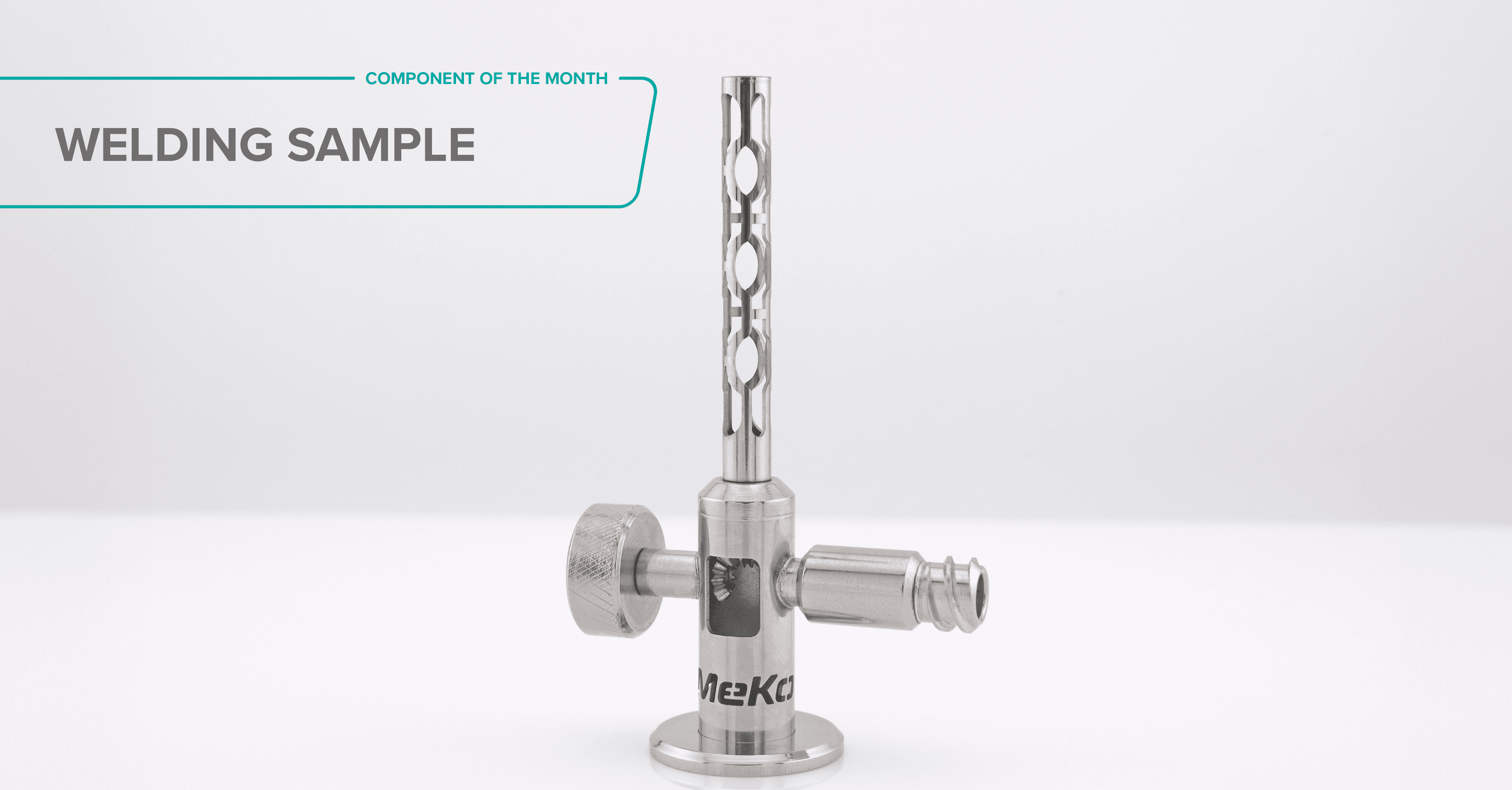

This month, we take a closer look at a new component that brings the possibilities of microjoining into focus: our laser welding demonstrator.

At first glance, it looks like a simple assembly. But it’s designed to show just how diverse — and precise — laser welding can be at micro scale. Each section highlights a different application, from joining tasks to functional movement.

The demonstrator features several common seam types: circular seams, butt welds (I- and V-joint), fillet welds, and square butt joints. These are used across real-world applications like a 3D weld on a cylindrical housing, a marker weld for part traceability, and a pin weld joining dissimilar metals. Additionally, gear elements are welded just enough to rotate freely, demonstrating how functionality can be preserved through precise joining.

These details aren’t just for show. They reflect real manufacturing needs in medical and precision industries, where clean seams, consistency and minimal thermal input are critical.

At MeKo, we develop custom demonstrators to make our processes more tangible. Some concepts only become clear when you can hold them in your hand — and that hands-on understanding is just as important to us as the technical solution itself.