The Nickel Free Vascular Alloy for Implants

Studies show that approximately 13 % of the population are allergic to nickel with a strong upward trend. Other people suffer from cobaltism. Therefore, MeKo has developed an implant alloy especially dedicated to vascular applications like stents. VASCULOY® improves the biocompatibility through freedom of nickel and freedom of cobalt.

VASCULOY® - The vascular alloy you can rely on.

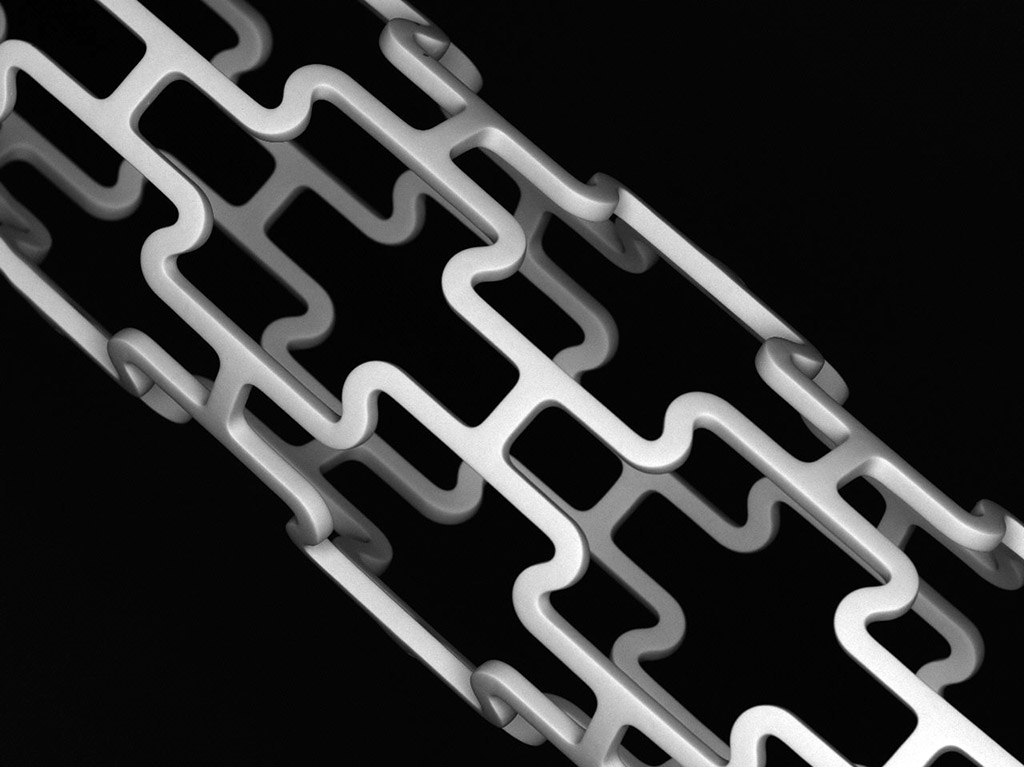

The mechanical properties of VASCULOY® like strength and break elongation are superior to 316L (316LVM) and comparable to L605. As a matter of principle the recent L605 stent designs can be switched to VASCULOY® without design changes. Therefore, stent designs with thin struts, high flexibility and positive clinical results are ensured.

The corrosion resistance of VASCULOY® is far better in comparison to 316L (316LVM) and L605. The Protection Potential, an important attribute for stents, is significantly higher. The reduced ion release of VASCULOY® is a great advantage for stents.

VASCULOY® is MRI compatible. Compared to 316L (316LVM), the artifacts are reduced by 55 %.

The biocompatibility of VASCULOY® has been proven with no limitation or restrictions.

Truly nickel free, VASCULOY® is superior to all commonly used implant materials.

For nickel-allergic persons the restenosis rate will be reduced.

VASCULOY® is produced utilizing high quality melting processes to assure microstructural integrity and cleanliness. These features facilitate brilliant products with a high-quality surface finish. In combination with the excellent mechanical properties, superior corrosion resistance, MRI-compatibility and unrestricted biocompatibility outstanding stent performances are ensured, differentiating VASCULOY® from other stent materials.

Mechanical Properties

MRI compatibility

Corrosion test data from cyclic potentiodynamic polarization measurements

Biocompatibility investigations according to ISO 10993

While many areas of application have already focused on using nickel-free alloys, up to now there has not been a suitable material for implants. A nickel allergy can lead to complications such as an increased rate of restenosis with implanted stents.

But now in January 2020, the first 36 stents made of VASCULOY® were implanted at a specialized center for cardiology in Bangalore, India. "We see a great need in this area, and are giving medical companies the opportunity to implement their ideas, using a material that's well-tolerated by all patients," explained MeKo owner Dr. Meyer-Kobbe.

1. Is there a chemical composition datasheet of Vasculoy®?

| Chromium | 14,0-16,5 |

| Iron | balance (~69,% |

| Cobalt | -- |

| Carbon | 0,10-0,20 |

| Manganese | 10,0- 12,0 |

| Molybdenum | 3,0-4,0 |

| Nickel | Max. 0,05 |

| Phosphorus | Max. 0,05 |

| Platinum | -- |

| Sulfur | -- |

| Silicon | Max. 0,50 |

| Nitrogen | 0,55-0,70 |

| Tungsten | -- |

2. How is Vasculoys® wear resistance?

The wear resistance has to be tested for the specific tribological conditions. As the mechanical properties of Vasculoy® are nearly identical to L605 a similar wear resistance is assumed.

3. In what form is Vasculoy® available?

Vasculoy® is available as tube, sheet and wire.

4. How does Vasculoy® compare to other Ni-free stainless steel such as ASTM F2229?

Vasculoy® shows a similar chemical composition as specified in ASTM F2229 (and also F2581) but with lower Manganese and Chromium content and slightly lower Nitrogen content. The chemical composition of Vasculoy® ensures a high strength combined with a high break elongation. Especially the Nitrogen content is adjusted in a very small range.

5. How does the weldability of Vasculoy® compare to other stainless steels and CoCr alloys?

The weldability of Vasculoy® is as good as for stainless steel and CoCr alloys.

6. How do the mechanical properties of Vasculoy® compare to those of MP35N?

The mechanical properties of Vasculoy® are like MP35N (slightly higher strength, slightly lower break elongation) but MP35N has 35 % Nickel!

7. What is the difference between the performance of Nitinol and Vasculoy®?

NiTi is a totally other class of material. Its super-elasticity makes a comparison of the mechanical properties difficult. Strength is about 20 % higher. The elastic elongation is 10 times better than for Vasculoy, L605 or 316L. But NiTi has about 50 % Nickel.

8. Are there already clinical studies of Vasculoy®?

Clinical studies have been implemented and the next bigger clinical studies for Vasculoy® stents will start in a few weeks.

9. Is Vasculoy® available for sale?

The processing of Vasculoy® should be performed by MeKo as the content of Nitrogen has to be preserved in a tight range and the electro-polishing needs special expertise as the material is highly chemical/corrosion resistant.