With about 25 years of experience as a supplier of components (e.g. stents) for medical devices, MeKo is the ideal partner for medical device companies.

With about 25 years of experience as a supplier of components (e.g. stents) for medical devices, MeKo is the ideal partner for medical device companies.

MeKo offers a wide range of services - from selecting the most suitable material to cleanroom packaging:

CAD / CAM

- Import of your design:

.dwg, .dxf, .step, .iges - Finite Element Analysis (FEA)

Material / Tube Selection

- Material of highest quality:

316L (316LVM), L605, Phynox, MP35N, - VASCULOY®: Ni-free alloy

- NiTi

- Resorbable materials: Mg, RESOLOY®, PLLA, ...

- More than 2,000 different tube lots on stock

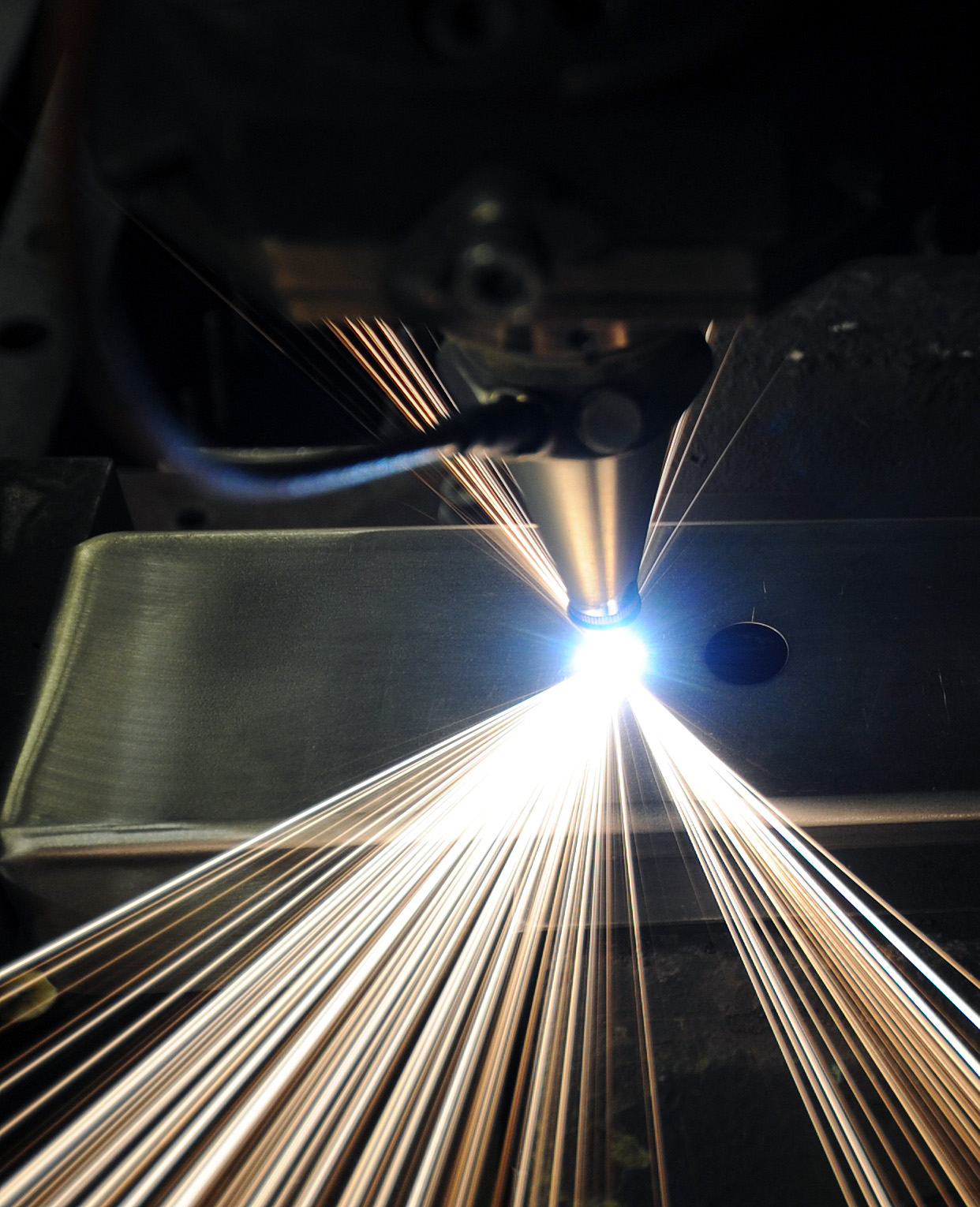

- High-end laser systems

- Precision, burr free laser cutting

- Tolerances less than ± 5 µm (± 0.0002“)

- Spot welding and seam welding

- Helium tight

- In-process quality control

- Special equipment developed in-house

- Exceptional smooth stent surfaces

- Round edges

- Improved corrosion resistance

- Extremely fine grain sizes achievable

- For CoCr: LowElast process for tight control of mechanical properties

- For NiTi: Shape setting and Af temperature setting, DSC and BFR measuring

- 100 % visual inspection of all implants

- More than 60 special high-end microscopes - visual and automatic

- High resolution microscopes

- Automated measuring systems

- Confocal laser scanning microscope (CLSM)

- Tensile testing

- Radial strength testing of stents

- Cross section and grain analysis

- Surface roughness

- Scanning Electron Microscope (SEM)

- Energy Dispersive X-ray Spectroscopy (EDS)

- Bend and Free Recovery (BFR)

- Differential Scanning Calorimeter (DSC)

- Electrochemical Impedance Spectroscopy (EIS)

- Potentiodynamic tests

- Degradation tests of bioresorbable materials

- ...